-

Hogar

-

Producto

-

-

NE-2 color naranja

NE-2 color naranja NE-2H color rojo

NE-2H color rojo

-

-

-

410 613 Lámpara de neón con resistencia, cable y funda, tubos de neón con resistencia

410 613 Lámpara de neón con resistencia, cable y funda, tubos de neón con resistencia 513 616 Lámpara de neón con resistencia y cable y manguito y terminal de anillo terminal L

513 616 Lámpara de neón con resistencia y cable y manguito y terminal de anillo terminal L E10BA9S Carcasa de plástico Soldadura de estaño, soldada a tope, engarzada Lámparas incandescentes de neón

E10BA9S Carcasa de plástico Soldadura de estaño, soldada a tope, engarzada Lámparas incandescentes de neón Tipo de fusible Lámpara de neón Soldadura de estaño, soldada a tope, engarzada con resistencia para lápiz de prueba

Tipo de fusible Lámpara de neón Soldadura de estaño, soldada a tope, engarzada con resistencia para lápiz de prueba

-

-

-

Lámparas indicadoras de neón de 6 mm, lámparas indicadoras con resistencia y cable de PVCCable de silicona

Lámparas indicadoras de neón de 6 mm, lámparas indicadoras con resistencia y cable de PVCCable de silicona Lámparas indicadoras de neón de 10 mm, luces de señalización con cable de PVC

Lámparas indicadoras de neón de 10 mm, luces de señalización con cable de PVC Lámparas indicadoras de neón de 12 mm color rojo con cable de PVC con resistencia prensada

Lámparas indicadoras de neón de 12 mm color rojo con cable de PVC con resistencia prensada

-

-

-

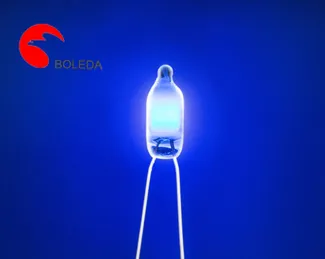

Lámparas LED de 3 mm y 5 mm con resistencia y cable.

Lámparas LED de 3 mm y 5 mm con resistencia y cable. Luz Led 3mm5mm, lámpara LED con resistencia y diodo.

Luz Led 3mm5mm, lámpara LED con resistencia y diodo.

-

-

-

Leds redondos de 3 mmPajitaforma plana, transparente como el aguadifuso

Leds redondos de 3 mmPajitaforma plana, transparente como el aguadifuso Leds redondos de 5 mm, forma plana, transparente como el agua.

Leds redondos de 5 mm, forma plana, transparente como el agua.

-

-

- Aplicaciones

- Sobre nosotros

- Noticias

-

Contáctenos

Comentario

(0)