Integrating indicator lamps with automation systems is a common and essential practice in many industrial and commercial settings. Indicator lamps are used to provide visual feedback to operators or maintenance personnel about the status of equipment, processes, or systems. By integrating indicator lamps with automation systems, these visual indicators can be controlled and activated based on specific events, alarms, or conditions within the automation system. This not only enhances the efficiency and reliability of the automation system but also enables operators to easily monitor and respond to changes in the system.

There are several ways to integrate indicator lamps with automation systems, depending on the type of automation system and the specific requirements of the application. In this article, we will discuss some common methods and best practices for integrating indicator lamps with automation systems.

1. Selection of Indicator Lamps

Before integrating indicator lamps with an automation system, it is important to select the appropriate type of indicator lamp for the application. Indicator lamps come in a variety of sizes, colors, brightness levels, and form factors, so it is essential to choose lamps that are suitable for the specific environment and conditions in which they will be used. For example, in a high-noise environment, it may be necessary to use brighter or larger indicator lamps to ensure that they are visible to operators. Similarly, in an outdoor setting, weather-resistant indicator lamps may be required to withstand exposure to the elements.

2. Wiring and Connectivity

Once the appropriate indicator lamps have been selected, the next step is to establish the wiring and connectivity between the indicator lamps and the automation system. In many cases, indicator lamps are connected to the automation system using low-voltage electrical signals, such as 24V DC. These signals can be directly controlled by the automation system through relays, programmable logic controllers (PLCs), or other control devices. It is important to ensure that the wiring and connections are properly installed and secured to prevent any electrical hazards or malfunctions.

3. Programming and Configuration

After the indicator lamps have been physically connected to the automation system, the next step is to program and configure the automation system to control the activation of the indicator lamps based on specific events or conditions. This may involve writing custom scripts or programming logic in the automation software to monitor sensors, inputs, or alarms and trigger the activation of the indicator lamps accordingly. For example, an indicator lamp may be programmed to turn on when a machine is in operation or to flash when a critical alarm is triggered.

4. Testing and Validation

Once the indicator lamps have been integrated with the automation system and programmed to function as intended, it is essential to conduct thorough testing and validation to ensure that the indicator lamps are working correctly and providing the desired visual feedback. This may involve simulating various events or conditions in the automation system to observe how the indicator lamps respond and verifying that they accurately reflect the status of the system. Any issues or discrepancies should be addressed and resolved before deploying the integrated system in a production environment.

5. Maintenance and Monitoring

After the indicator lamps have been successfully integrated with the automation system, it is important to establish a maintenance and monitoring plan to ensure that the indicator lamps continue to function reliably over time. This may include conducting regular inspections of the indicator lamps, cleaning or replacing lamp bulbs as needed, and monitoring the connectivity and functionality of the indicator lamps within the automation system. Additionally, any software updates or changes to the automation system should be tested to verify that they do not affect the operation of the indicator lamps.

In conclusion, integrating indicator lamps with automation systems is a straightforward process that can significantly enhance the efficiency and effectiveness of industrial and commercial operations. By selecting the appropriate indicator lamps, establishing proper wiring and connectivity, programming and configuring the automation system, testing and validating the integration, and implementing a maintenance plan, operators can ensure that indicator lamps provide accurate and reliable visual feedback in conjunction with automation systems. This enables operators to easily monitor and respond to changes in the system, improving overall productivity and safety in the workplace.

NE-2 color naranja

NE-2 color naranja NE-2H color rojo

NE-2H color rojo 410 613 Lámpara de neón con resistencia, cable y funda, tubos de neón con resistencia

410 613 Lámpara de neón con resistencia, cable y funda, tubos de neón con resistencia 513 616 Lámpara de neón con resistencia y cable y manguito y terminal de anillo terminal L

513 616 Lámpara de neón con resistencia y cable y manguito y terminal de anillo terminal L E10BA9S Carcasa de plástico Soldadura de estaño, soldada a tope, engarzada Lámparas incandescentes de neón

E10BA9S Carcasa de plástico Soldadura de estaño, soldada a tope, engarzada Lámparas incandescentes de neón Tipo de fusible Lámpara de neón Soldadura de estaño, soldada a tope, engarzada con resistencia para lápiz de prueba

Tipo de fusible Lámpara de neón Soldadura de estaño, soldada a tope, engarzada con resistencia para lápiz de prueba Lámparas indicadoras de neón de 6 mm, lámparas indicadoras con resistencia y cable de PVCCable de silicona

Lámparas indicadoras de neón de 6 mm, lámparas indicadoras con resistencia y cable de PVCCable de silicona Lámparas indicadoras de neón de 10 mm, luces de señalización con cable de PVC

Lámparas indicadoras de neón de 10 mm, luces de señalización con cable de PVC Lámparas indicadoras de neón de 12 mm color rojo con cable de PVC con resistencia prensada

Lámparas indicadoras de neón de 12 mm color rojo con cable de PVC con resistencia prensada Lámparas LED de 3 mm y 5 mm con resistencia y cable.

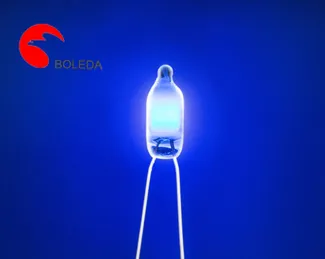

Lámparas LED de 3 mm y 5 mm con resistencia y cable. Luz Led 3mm5mm, lámpara LED con resistencia y diodo.

Luz Led 3mm5mm, lámpara LED con resistencia y diodo. Leds redondos de 3 mmPajitaforma plana, transparente como el aguadifuso

Leds redondos de 3 mmPajitaforma plana, transparente como el aguadifuso Leds redondos de 5 mm, forma plana, transparente como el agua.

Leds redondos de 5 mm, forma plana, transparente como el agua.

Comentario

(0)