Indicator lamps are an essential component in process control systems as they provide visual feedback on the status of various elements within the system. These lamps are used to signal if certain conditions are met or if there is an issue that needs attention. They are commonly used in industrial processes, manufacturing facilities, and other control systems where real-time monitoring is crucial.

One of the primary roles of indicator lamps in process control systems is to provide operators with immediate feedback on the status of different components within the system. For example, a red indicator lamp may signify that a certain parameter is out of the acceptable range, while a green lamp may indicate that everything is running smoothly. This visual indication allows operators to quickly assess the situation and make informed decisions accordingly.

Indicator lamps also play a crucial role in alerting operators to any malfunctions or abnormalities within the system. By using different colors, blinking patterns, or flashing sequences, these lamps can convey important information about the nature of the issue, its severity, and the necessary actions to be taken. This helps operators pinpoint the problem more quickly and efficiently, reducing downtime and minimizing the risk of potential damage.

Moreover, indicator lamps are used to indicate the status of different processes or functions within the system. For instance, a flashing yellow lamp may signal that a specific operation is in progress, while a steady blue lamp may indicate that a certain component is activated. By providing this real-time feedback, these lamps help operators monitor the progress of various tasks and ensure that everything is working as intended.

In addition, indicator lamps are crucial for safety purposes in process control systems. By using bright, easily recognizable colors and symbols, these lamps can quickly draw attention to critical situations that require immediate action. For example, a flashing red lamp may indicate a safety hazard that needs to be addressed promptly, prompting operators to take appropriate measures to prevent accidents or damage.

Furthermore, indicator lamps can be used for diagnostic purposes in process control systems. By analyzing the patterns and sequences of the lamps, operators can identify recurring issues, trends, or patterns that may indicate underlying problems within the system. This information can then be used to troubleshoot issues, optimize processes, and improve overall system performance.

Overall, indicator lamps play a vital role in process control systems by providing operators with essential visual feedback on the status of various components, processes, and functions within the system. By using different colors, blinking patterns, and symbols, these lamps help operators monitor operations, detect issues, ensure safety, and optimize performance. As such, indicator lamps are a critical tool for effective process control and monitoring in a wide range of industrial and manufacturing applications.

NE-2 color naranja

NE-2 color naranja NE-2H color rojo

NE-2H color rojo 410 613 Lámpara de neón con resistencia, cable y funda, tubos de neón con resistencia

410 613 Lámpara de neón con resistencia, cable y funda, tubos de neón con resistencia 513 616 Lámpara de neón con resistencia y cable y manguito y terminal de anillo terminal L

513 616 Lámpara de neón con resistencia y cable y manguito y terminal de anillo terminal L E10BA9S Carcasa de plástico Soldadura de estaño, soldada a tope, engarzada Lámparas incandescentes de neón

E10BA9S Carcasa de plástico Soldadura de estaño, soldada a tope, engarzada Lámparas incandescentes de neón Tipo de fusible Lámpara de neón Soldadura de estaño, soldada a tope, engarzada con resistencia para lápiz de prueba

Tipo de fusible Lámpara de neón Soldadura de estaño, soldada a tope, engarzada con resistencia para lápiz de prueba Lámparas indicadoras de neón de 6 mm, lámparas indicadoras con resistencia y cable de PVCCable de silicona

Lámparas indicadoras de neón de 6 mm, lámparas indicadoras con resistencia y cable de PVCCable de silicona Lámparas indicadoras de neón de 10 mm, luces de señalización con cable de PVC

Lámparas indicadoras de neón de 10 mm, luces de señalización con cable de PVC Lámparas indicadoras de neón de 12 mm color rojo con cable de PVC con resistencia prensada

Lámparas indicadoras de neón de 12 mm color rojo con cable de PVC con resistencia prensada Lámparas LED de 3 mm y 5 mm con resistencia y cable.

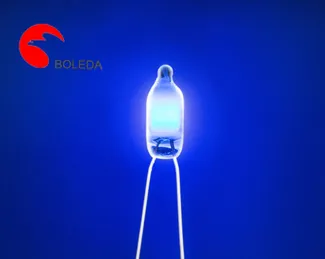

Lámparas LED de 3 mm y 5 mm con resistencia y cable. Luz Led 3mm5mm, lámpara LED con resistencia y diodo.

Luz Led 3mm5mm, lámpara LED con resistencia y diodo. Leds redondos de 3 mmPajitaforma plana, transparente como el aguadifuso

Leds redondos de 3 mmPajitaforma plana, transparente como el aguadifuso Leds redondos de 5 mm, forma plana, transparente como el agua.

Leds redondos de 5 mm, forma plana, transparente como el agua.

Comentario

(0)